What is Plinth Beam?

A plinth beam is a reinforced concrete beam constructed at the plinth level of a building. It is constructed between the foundation and the walls of the building. It is the horizontal member that connects all the columns at the plinth level of a structure. It runs along the periphery of the building, forming a closed loop. It also reduces the slenderness ratio of the columns.

The plinth beam divides the superstructure from the foundation and behaves as a tie beam by connecting walls and columns.

Purpose of Plinth Beam

- The main function of a Plinth Beam is to evenly distribute the load of the superstructure to the foundation.

- It ensures that the weight of the building is distributed uniformly, without any excessive stress on individual columns.

- It provides lateral support to the columns, ensuring the structure withstands horizontal forces, during the earthquake or seismic activity.

- It acts as a barrier between the building structure and the ground to protect against moisture from seeping into the building causing dampness.

- It provides stability to the walls of the building.

- It prevents the cracks as the foundation settles.

- It can be created to improve the appearance of the building.

- Providing safeguard, the structure from destructive pests.

- It provides the building with strength and longevity.

- Homes are often constructed 150–300 mm above the road level. The plinth acts as a retaining wall for the compacted dirt that occupies the space between the foundation and the top of the plinth.

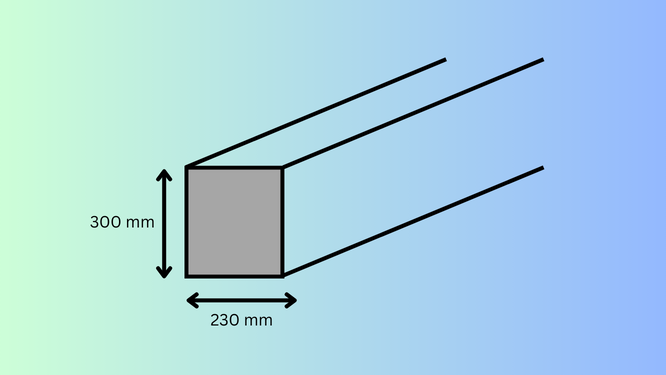

What is the size of the Plinth Beam?

The size may vary depending on the design and load-bearing requirements of the building. Generally, the width of a plinth beam ranges from 9 inches (230 mm) to 12 inches (300 mm), and the thickness may vary from 300mm to 600mm. It keeps the structure at a sufficient height from the road level.

Difference between Plinth Beam and Tie Beam

Plinth Beams are located at the plinth level of the building. The tie beams are located at a higher level than the plinth beam of the building connecting columns.

It is designed to distribute the loads of the columns to the foundation. Its purpose is to withstand lateral stresses, such as wind or seismic loads, and stop the building from swaying or collapsing.

It prevents the development of cracks in the structure. It prevents the buckling of the columns.

Material Requirements for Construction

The following materials are required for the construction of the plinth beam:

Reinforcement: Steel bars are fixed as per the specification to reinforce the beam. In the tension zone of the beam, the minimum diameter of the reinforcement bar should not be less than 12mm. For the compression zone, the diameter of the reinforcing bar should not be less than 10mm.

A clear cover of 25mm should be provided to keep the reinforcement safe from harmful weather effects.

The minimum diameter of the reinforcement used for stirrups should not be less than 6mm.

Formwork: Proper formwork should be placed around the reinforcement of the plinth beam, ensuring the dimensions of the beam.

Concrete: After the formwork completed, concrete is poured into it. The preferred grade of concrete for casting is M20.

Also Read:

Procedure to the M20 Grade Mix Design of Concrete

Plinth Beam Protection

The protection of the plinth is important to prevent the infiltration of water in the soil that reaches the plinth wall and reaches the floor level through capillary action.

Plinth protection is a zone around the building that is typically created by pouring a layer of Plain cement concrete that is about 100 mm thick. It also provides a clean surface for placing the reinforcement.

Construction of Plinth Beam

- Firstly, clear the construction site on a properly leveled surface, so that marking can be done easily.

- Now mark the center line of the plinth beam from column to column, and also mark the width by taking measurements on either side of the plinth beam. Eg: Width/2

- Now place the reinforcement according to the bar bending schedule and proper care should be taken to provide adequate cover to the reinforcement to prevent corrosion.

- The next step is to erect the formwork of plywood or steel plates with proper line and alignment to get the desired width as marked.

- Now pour the concrete of the required mix to cover the reinforcement. Use a vibrator to remove air bubbles and ensure proper compaction.

- Open the formwork after 24 hours and allow the concrete to cure for 7-8 days to achieve its desired strength.

Advantages

The following are the advantages of the plinth beam:

- It prevents the differential settlement of the structure.

- It prevents the development of cracks.

- It uniformly distributes the load from columns to the foundation.

- It prevents the entry of moisture or dampness from the soil to the structure.

- It provides a leveled surface for brickwork.

- It keeps the structure safe from water and termites which may affect the life of the plinth.

FAQs

What is Plinth Level?

The Plinth Level lies between the top of the pedestal of the footing and the floor level of the building.

It is the level from where the brickwork starts.

Is DPC required for plinth beam?

In frame structures where a plinth beam is constructed, DPC is not required as the beam itself is an impermeable block. But in some cases, bitumen coating is applied on the top of the beam.

Why is a plinth beam necessary?

It is necessary to withstand the uneven settlement of the foundation of the building. It also acts as an impermeable block against moisture and dampness.

What is the ideal depth and width of a plinth beam?

The depth and width of a plinth beam depend on various factors such as the load acting on the structure, soil conditions, and the design requirements. But generally, for a 1-storey building, it is taken as (230 x 300mm).

Which grade of concrete is used for the plinth beam?

M20 is the grade of concrete usually preferred for casting of plinth beam.

Also Read:

Singly Reinforced Beam and Doubly Reinforced Beam Working Stress Method, Ultimate load, and Limit State Method 13 Best Types of Cement For Concrete Mix