Working Stress Method

The working stress method was the oldest method of design. It is based on the elastic design method and focuses on ensuring that the stress induced in a structural element, under the working or service loads, remains within safe limits. It means that the stress is directly proportional to strain up to the point of collapse. It assumes that the bond between steel and concrete is perfect and that permissible stresses of the materials are obtained.

In this procedure, the yield strength or 0.2% proof stress of steel and the ultimate strength of concrete is divided by the factor of safety to determine the allowable stresses. These safety considerations account for the uncertainties involved in the production of these materials. According to IS456, safety factors in working stress method are:

For Concrete – (a) in bending compression – 3.0

(b) in direct compression – 4.0

For steel – 1.78

Permissible stress = Strength of material/ Factor of safety

Assumptions by Working Stress Method

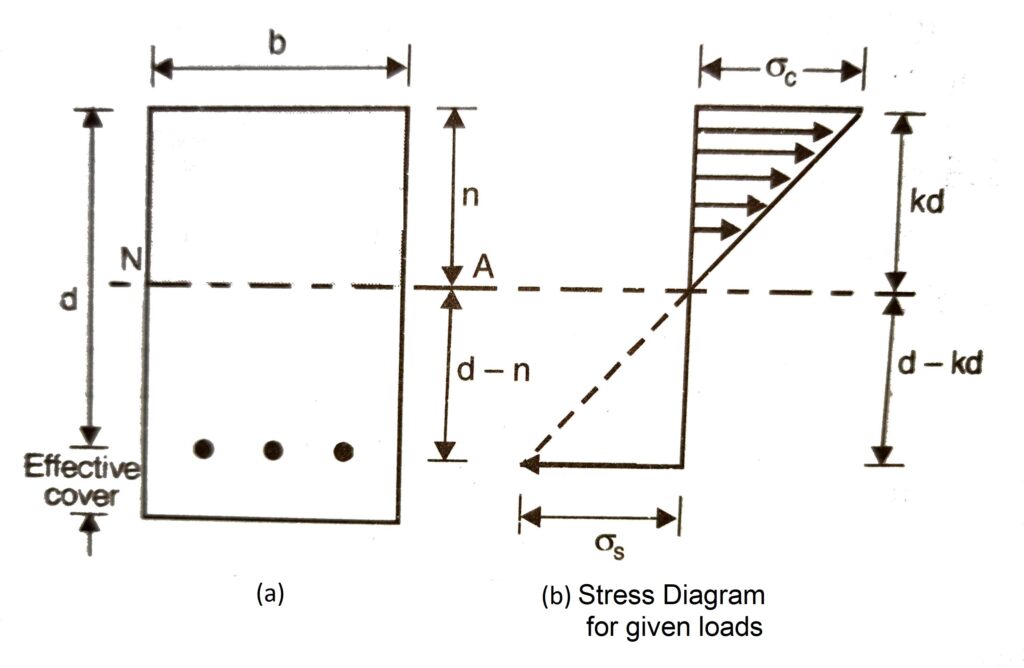

The elastic theory of bending and simple straight line theory forms the basis of the working stress method of design. Assumptions of the elastic theory of bending are given below:

- A section that is plane before bending remains plain after bending.

- The concrete and steel reinforcement are perfectly bonded.

- All tensile stress is taken up by steel and none by concrete.

- The stress-strain relationship of steel and concrete under working loads is a straight line.

- The modulli of elasticity of steel (Es) and concrete (Ec) is constant.

- The modular ratio (m) has the value 280/3σcbc, where σcbc is the permissible compressive strength of concrete in bending is N/mm2.

- There are no initial stresses in steel and concrete.

Limitations of Working Stress Method

- It assumes that concrete is elastic which is not true as the concrete behaves inelastically even at low temperatures.

- It is a factor of safety for stress only and not for loads. Hence, this method does not give two margins of safety with respect to loads because we do not know the failure load.

- It does not use any factor of safety with respect to loads. It means, there is no provision for the uncertainties associated with the estimation of loads.

- It does not account for shrinkage and free which are time-dependent and plastic in nature.

- This method gives an uneconomical section.

- It pays no attention to the conditions that arise at the time of collapse.

Ultimate Load Method

This approach uses ultimate or collapse load as the design load. The ultimate loads are obtained by increasing the working/service loads suitably by some factors. The term “load factor” refers to those variables that are multiplied by the working loads to yield the ultimate loads. These load factors give the exact margin of safety in terms of load. This method uses the real stress-strain curve of concrete and steel and takes into account the plastic behavior of these materials.

Many designers feel that the load factor provides a clear margin of safety and one can easily tell the load at which the structure fails, which is not clear from the working stress concept of permissible stresses. According to IS456-1964, the advantages of this method are listed below:

- The method is more realistic as compared to the working stress method because the ultimate load method takes into account the non-linear behavior of the concrete.

- This method gives an exact margin of safety in terms of load, unlike the working stress method which is based on the permissible stresses which do not give any idea about the failure/collapse load.

- The sections designed by the ultimate load method are thinner and require less reinforcement. Hence the method is economical as compared to the working stress method.

The main limitations of the ultimate load method are the following:

- This method gives very thin sections which leads to excessive deformation and cracking, thus making the structure unserviceable.

- No factors of safety are used for material stresses.

As serviceability requirements are not satisfied at all in this method, the code replaced this method with a limit state method which takes into account the strength as well as serviceability requirements.

Limit State Method

This is the most rational method which takes into account the ultimate strength of the structure and also the serviceability requirement it is a judicious combination of working stress and the ultimate load method of design. The acceptable limit of safety and serviceability requirements before failure occurs is called the limit state. This method is based on the concept of safety at ultimate loads and serviceability at working loads. The two important limit states to consider in design are:

- Limit state of collapse.

- Limit state of serviceability.

FAQs

Where is the working stress method used?

The Working Stress Method is still relevant for many structural designs, especially for routine structures like buildings and bridges. However, for complex or critical structures, engineers often opt for the Limit State Method due to its flexibility and accuracy.

What is the difference between WSM and LSM?

WSM focuses on ensuring structural safety within the elastic range of materials under service loads, relying on safety factors. In contrast, LSM considers both ultimate and serviceability limit states, applying partial safety factors to loads and material strengths, resulting in more efficient and effective designs.

What are the advantages of WSM?

The design usually gives more thicker sections of structural members as compared to LSM. Due to this, the structure design by WSM gives better performance in terms of serviceability requirements, i.e. less deflection, cracking, etc.

What is a factor of safety formula?

For concrete: Factor of safety = Ultimate strength / Working stress.

For steel: Factor of safety = Yield strength / Working stress.

On which theory of the WSM method based?

It is based on the elastic theory which assumes that both steel and concrete are elastic and follows Hooke’s Law. It means stress is directly proportional to strain up to the point of collapse.

Also Read:

Procedure to the M20 Grade Mix Design of Concrete Types of Aggregates (Coarse and Fine aggregates) | Properties and Use Singly Reinforced Beam and Doubly Reinforced Beam