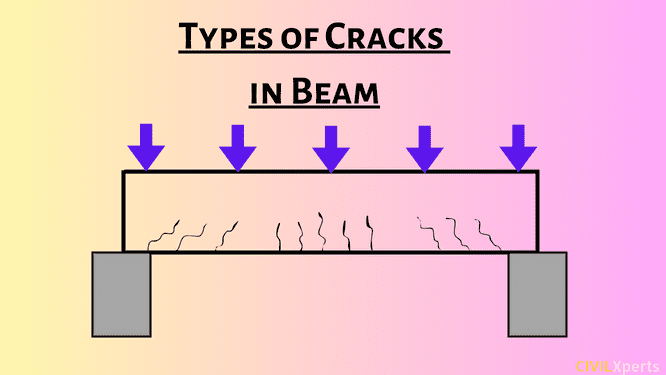

Types of cracks in beams are common in concrete beams when the beam is subjected to shear force and bending moment. However, over time, beams can develop cracks due to various factors. The types of cracks in the reinforced concrete beams are described in detail.

WHAT IS BEAM?

A beam is a flexural member designed to support the loads and resist bending. It is a horizontal or inclined structural member that spans open spaces and carries the structure’s weight or the loads imposed on it. The most common types of beam cross-sections include rectangular, I-shaped (also known as an I-beam or H-beam), T-shaped, and L-shaped.

TYPES OF CRACKS IN BEAMS

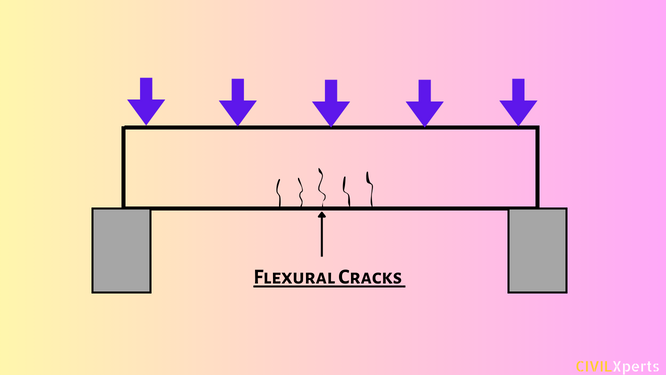

Flexural Cracks

When a beam is subjected to transverse load, the maximum shear force occurs at the supports. At the tension zone of the beam, it is subjected to bending tensile stress as well as shear stress. At the midspan, the bending moment is maximum and the shear force is zero. Thus, the stress developed tries to pull apart the section and gives a vertical crack.

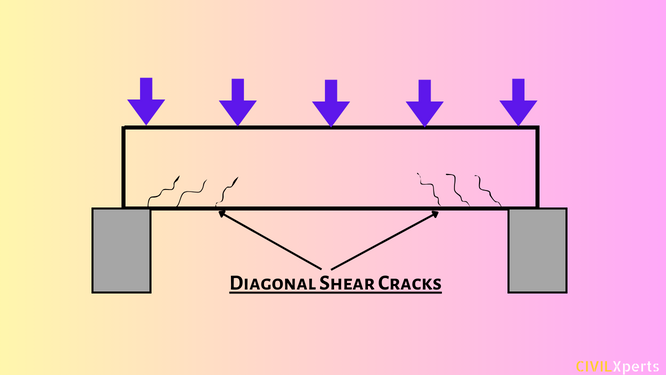

Diagonal Shear Cracks

At or near the supports, there is no bending stress but maximum shear stress. Under this stressed condition the beam is subjected to tensile stress. As the concrete is weak in tension it splits diagonally (45°)and the cracks developed are diagonal.

Thus, this type of tension is also called diagonal tension which is caused by shear and cannot be resisted by concrete alone. So shear reinforcement is provided in the beams to take diagonal tension and prevent cracking of the beam.

At or near the center, the cracks will be vertical.

At or near the supports the cracks are inclined at 45°.

In between the supports and midspan, the cracks may vary from 45° to 90°.

Settlement or Shrinkage Cracks

Settlement or shrinkage cracks in beams occur as a result of uneven settling or drying of the materials used in construction. These cracks are typically vertical and can be found in both reinforced and unreinforced concrete beams. Poor compaction of soil, inadequate curing, or rapid drying can lead to settlement or shrinkage cracks.

Corrosion Cracks

Corrosion cracks are a significant concern in beams constructed with steel reinforcement. When steel reinforcement is exposed to moisture and oxygen, it can corrode, leading to the expansion of the steel and subsequent cracking of the surrounding concrete. These cracks in beams often appear in a radial pattern around the corroded reinforcement.

Fatigue Cracks

Fatigue cracks occur in beams subjected to repetitive loading or cyclic stress over an extended period. Since these fissures are often small and cannot be noticed at first. However, if they are not repaired, they can expand and lead to structural failure. Fatigue cracks in beams often appear as fine lines perpendicular to the direction of the applied stress.

PREVENTION AND REPAIR OF CRACKS IN BEAMS

To prevent and repair cracks in beams, several effective methods can be employed:

Adequate Reinforcement

Ensuring proper shear reinforcement design and installation can significantly enhance the load-carrying capacity of the beam and minimize the risk of cracks and failure.

By improving quality

Employing skilled labor, following approved construction practices, and using high-quality materials can help prevent cracks in beams.

Regular and Proper Maintenance

Regular inspections, monitoring, and timely maintenance help to identify cracks at an early stage, preventing further deterioration.

Crack Filling

Injecting epoxy or other suitable materials into cracks can effectively repair them, restoring the structural strength of the beam.

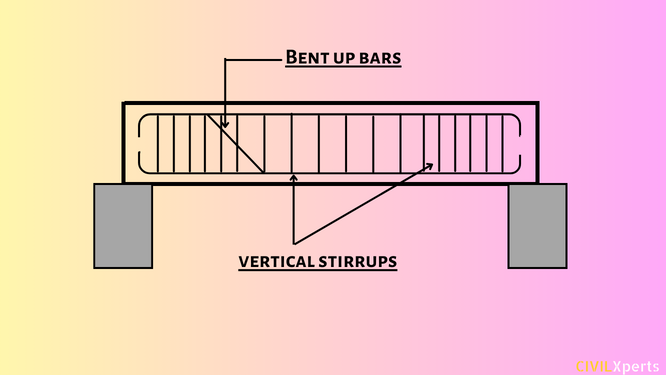

TYPES OF SHEAR REINFORCEMENT IN BEAMS

Shear reinforcement is of three types:

- Vertical stirrups

- Bent-up bars along with stirrups

- Inclined stirrups

Vertical Stirrups

These are the steel bars that are vertically positioned at specific intervals along the length of the beam. Their diameter varies from 6mm to 16mm. The free ends of the stirrups are anchored in the compression zone of the beam to the anchor bars or the compressive reinforcement.

Depending upon the magnitude of the shear force to be resisted the vertical stirrups may be one-legged, two-legged, four-legged, etc. It is desirable to use closely spaced stirrups to prevent diagonal cracks. Since shear force is maximum at the supports, the spacing of stirrups near the supports is less compared to spacing near the midspan.

Bent-up bars along with stirrups

Some of the longitudinal bars in a beam can be bent up near the supports where they are not required to resist the bending moment which is very less near the supports. These bent-up bars resist diagonal tension. An equal number of bars are to be bent on both sides to maintain symmetry. Along the length of the beam, the bars can be bent up equally at multiple points.

Typically, these bars are bent at a 45° angle. For stronger shear forces, this system is employed. The contribution of bent-up bars and vertical stirrups is added to determine the overall shear resistance of the beam. Not more than 50% of the total shear reinforcement is contributed by bent-up bars.

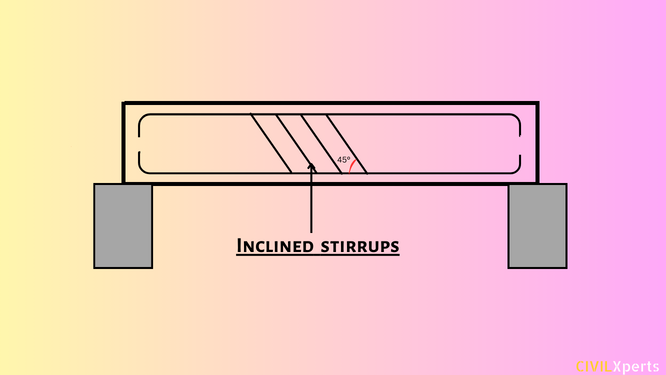

Inclined Stirrups

Inclined stirrups are offered, typically at a 45° angle, to counteract diagonal tension.

MAXIMUM SPACING OF STIRRUPS

The maximum spacing of vertical stirrups shall not exceed 0.75d or 300mm whichever is less. In the case of inclined stirrups at 45°, the maximum spacing should not be more than d or 300mm whichever is less.

SHEAR STRENGTH OF REINFORCED CONCRETE BEAM

The shear strength of a RCC beam depends upon the following factors:

Grade of Concrete

The shear resistance of concrete increases with the increase in the grade of concrete. The higher the grade of concrete, the more will be the shear strength.

Percentage of tensile reinforcement

The shear strength of reinforced concrete beams increases with the percentage of tensile reinforcement.

FAQs

What is the technique required for repairing cracks?

Grouting is suitable for wider cracks or when the cracks are caused by settlement or shrinkage. Grouting involves injecting a cement-based or epoxy-based grout into the cracks to fill and seal them.

How many types of Cracks are in beams?

There are mostly two types of cracks found in the beams i.e. Flexural or Shear. If a beam develops these kinds of cracks, it may need to be retrofitted to keep the loads within safe permissible limits.

Are cracks in beams always a cause for concern?

Even though not all beam cracks indicate serious structural problems, it is necessary to repair them right away. Even minor cracks have the potential to worsen over time and affect the strength of the beam.

Why do cracks occur in beams?

Cracks develop due to the bending tensile stress which occurs at the midspan of the beam and shear stress which develops near the midspan and at the supports of the beam.

What are the shrinkage cracks in beams?

Shrinkage cracks are caused by variations in the moisture content of the concrete. The intermolecular gap in the structure of concrete and mortar makes them permeable. When they absorb moisture, they expand, and contract when they dry.

What are the prevention of cracks?

Ensure a clear cover, adequate reinforcement, proper placement of concrete with vibrations, and quality control. Also, conduct regular inspections to identify any signs of cracking or distress in the beams.

CONCLUSION

A beam is a structural component that can support weight largely by resisting bending. The formation of cracks in beams affects the durability of the structure. Regular maintenance and timely repairs, when necessary, are important for preserving the structural strength of beams and ensuring the safety of the overall structure. If you notice any cracks in beams, it is advisable to seek a professional civil engineer who can evaluate the impact and recommend the best advice.

Plinth Beam |Purpose Construction and Advantages| Singly Reinforced Beam and Doubly Reinforced Beam Working Stress Method, Ultimate load, and Limit State Method