Mix Design is the process of determining the right proportions of the ingredients of concrete (cement, sand, and aggregate) to achieve the concrete of required strength and properties is called Mix Design Concrete. This is used for concrete grade M25 and above.

It is observed that mixed design makes the concrete in accurate proportions and also makes it economical. Mix design of concrete is used where large quantities of concrete are required such as Bridges, Buildings, dams, etc. IS 10262: 2009 gives recommendations for the design of concrete mixes.

Different Types of Concrete Mixes

Nominal Mix

Typically, a nominal mix is used for small-scale construction projects. In this, the ingredients of concrete in specified proportions are already fixed. Eg. M10 (1:3:6) is the grade of concrete and the quantity of cement, sand, and aggregate is batched in volume as a predetermined ratio.

Mix Design

Mix design of concrete refers to a specific combination of ingredients used in the production of concrete. In this type, the amount of quantities of the individual components of concrete are given by the engineer after proper analysis. While choosing the Mix Design Ratio, the Fineness Modulus and Specific Gravity of Cement are examined in the lab. Ingredients are batched by weight and there is no pre-fixed ratio.

Reference code – IS 10262: 2009

REPORT ON MIX DESIGN (M-20 GRADE CONCRETE)

STIPULATIONS FOR PROPORTIONING

(a) Grade Designation: M-20

(b) Type of Cement: PPC

(c) Maximum nominal size of aggregate: 20mm

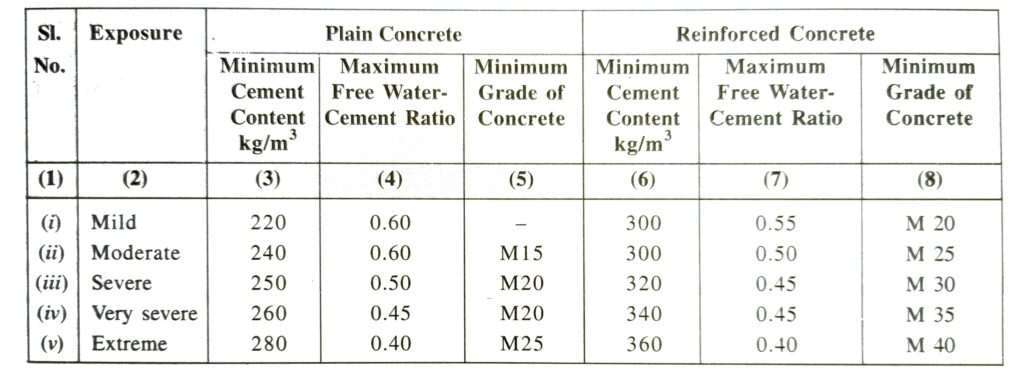

(d) Minimum Cement Content: 300 kg/m3

(e) Maximum water-cement ratio: 0.55

(f) Workability: SIump (25-50 mm)

(g) Exposure Condition: Mild

(h) Method of concrete pouring: Manual

(i) Degree of Supervision: Good

(j) Type of aggregate: Crushed Angular

(k) Maximum cement content: 450 kg/m3

1. Test Data for Material

(a) Cement Used: PPC

(b) Specific Gravity of Cement: 3.15

(c) Chemical admixture: No to be used

(d) Specific Gravity of

(1) Coarse aggregate

- 10 mm 2.62

- 20 mm 2.64

(2) Fine aggregate

- 10 mm 2.62

- 20 mm 2.64

(e) Water absorption

(1) Coarse aggregate

- 10 mm 2.62

- 20 mm 2.64

(2) Fine aggregate Nil

(f) Free Surface Moisture:

(1) Coarse aggregate Nil

(2) Fine Aggregate Nil

(g) Sieve analysis

(1) Coarse aggregate Confirming to table – 2 of IS-383:1970

(2) Fine aggregate Confirming to zone — II of table – 4 of IS-383:197

2. Target Strength for MIX Proportioning

f’ck = fck + 1.65 S

where

f’ck = target average compressive strength at 28 days

fck = Characteristics Compressive Strength at 28 days

S = Standard Deviation

From table – 1 of 456:2000 standard deviation S for M20 – 4 N/mm2

| Grade of Concrete | Assumed standard deviation |

| M10, M15 | 3.5 N/mm2 |

| M20, M25 | 4.0 N/mm2 |

| M30, M35, M40, M45, M50 | 5.0 N/mm2 |

Therefore, target strength (TMS)/f’ck =20+1.65 S

=20+1.65×4

=26.60 N/mm2

3. Selection of water-cement ratio

From table 5 of IS — 456:2000, Maximum Water Cement Ratio = 0.55 Adopt Water Cement Ratio as 0.516<0.55

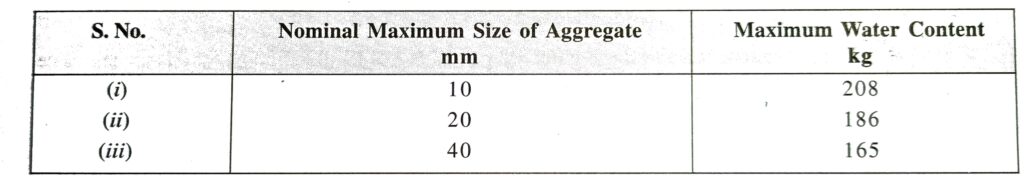

4. Selection of Water content

From Table 2, maximum water content = 186 Litre (for 25 to 50mm Slump range) for 20mm aggregate.

5. Calculation of cement content

Water cement ratio – 0.516

Cement – 186/0.516 = 360.47 kg (say 361 kg)

From table 5 of IS — 465, minimum cement content for mild exposure condition = 300 kg/m3 361 kg/m3 > 300 kg/ m3 hence ok.

6. Proportion of volume of Coarse Aggregate and Fine Aggregate

From Table 3 value of coarse aggregate corresponding to 20mm size aggregate and fine aggregate (zone II) for water cement ratio of 0.50 = 0.62

In the present case water cement ratio is 0.516 therefore, the volume of coarse aggregate is required to be increased to decrease the fine aggregate content. As the water-cement ratio is lower by 0.10 the proportion of volume of coarse aggregate is increased by 0.02 (@ -/+0.01) for every + 0.05 change in the water-cement ratio.

Therefore, the corrected proportion of the volume of coarse aggregate for the water-cement ratio of 0.516 = 0.66

The volume of fine aggregate = 1.00 – 0.66 — 0.34

7. Mix Design Calculation

Volume of concrete = 1.00 m3

Volume of cement =361/3.15 x 1/1000 = 0.1146 m3

Volume of water = 186/1000 = 0.186 m3

Volume of aggregate =1.00 – (0.114 + 0.186) = 0.700 m3

Mass of coarse aggregate = 0.700 x 0.66 x 2.63 x 1000 = 1215.06 kg (Say 1215 kg)

Mass of fine aggregate = 0.700 x 0.34 x 2.53 x 1000 = 602.14 kg (Say 602 kg)

8. Final ingredients of Mix design

Cement = 361 kg/ m3

WCR = 0.516

Water = 186 kg/ m3 Coarse aggregate

=1215kg/ m3 Fine aggregate = 602kg/ m3

9. Moisture correction

Moisture content in river sand = 3.25%

Moisture content in crusher dust = 3.01%

Weight of river sand = 602.14 x 0.3 = 180.642 kg

Moisture correction = 180.642 x 3.25/100 = 5.871 kg

Total Weight of river sand = 180.642 + 5.871 = 186.513 kg

Weight of crusher dust = 602.14 x 0.7 = 421.519 kg

Moisture correction = 421.519 x 3.01/100 = 12.688 kg

Total Weight of crusher dust = 421.519 + 12.688 = 434.207 kg

10. Weight of water

Add Water absorption in coarse aggregate = 1215.06 x 1.22/100 = 14.824kg

Subtract Water due to

(i) Moisture content in river sand = 180.642 x 3.25/100 = 5.871 kg

(ii) Moisture content in crusher dust = 421.519 x 3.01/100 = 12.688 kg

Final weight of water = 186 + 14.824 – 5.871 – 12.688 = 182.265 kg

11. Final ingredients of Mix Design after correction

Cement = 361 kg/ m3

Water = 182.265 kg/m3

Fine aggregate

- Crusher dust = 434.207 kg/m3

- River sand = 186.513 kg/m3

Coarse aggregate

- 20mm = 1215.06 x 0.55 = 668.283 kg/m3

- 10mm = 1215.06 x 0.45 = 546.777 kg/m3

Trial of Mix design of concrete (M-20) is done on-site using 15 kg cement and 4 samples of cubes

i.e. 12 cubes are filled after a proper mix of concrete.

Cement = 15 kg

Water = 7.573kg

Fine aggregate

Crusher dust = 18.043 kg

River sand = 7.749 kg

Coarse aggregate

20mm = 27.76 kg

10mm = 22.72 kg

Observations:

1. The slump of concrete has been checked and obtained at 35 mm.

2. Quality visibility is cohesive and good (no bleeding).

3. The 7-day compressive strength of concrete is tested and the results are as follows:

| Sr. no. | Wt. of Cube in gm | Load in KN | Strength of cube in N/mm2 | Average Strength | Remarks |

| 1. | 7925 | 425 | 18.89 | It is below required 7 days strength of 18.62 N/mm2 | |

| 2. | 7855 | 375 | 16.67 | 17.78 N/mm2 | |

| 3. | 7915 | 400 | 17.78 |

4. The 28 days compressive strength of concrete is:

| Sr. no. | Wt. of Cube in gm | Load in KN | Strength of cube in N/mm2 | Average Strength | Remarks |

| 1. | 8190 | 615 | 27.33 | 28.00N/mm2 | It is smaller than the required TMS 28 days strength of 26.60 N/mm2 |

| 2. | 8180 | 660 | 29.33 | ||

| 3. | 8105 | 615 | 27.33 | ||

| 4. | 8005 | 555 | 24.67 | 25.78 N/mm2 | It is smaller than the required TMS 28 days strength of 26.60 N/mm2 |

| 5. | 8090 | 620 | 27.56 | ||

| 6. | 8245 | 565 | 25.11 | ||

| 7. | 8140 | 580 | 25.78 | 25.63 N/mm2 | It is smaller than required TMS 28 days strength of 26.60 N/mm2 |

| 8. | 8250 | 585 | 26.00 | ||

| 9. | 8180 | 565 | 25.11 |

The second trial is done by varying water content and water cement ratio. Trial mixes 3 and 4 are created by keeping the water content at the predetermined level and changing the W/C ratio by 10%.

You can also read :

Reinforced Cement Concrete Best Properties, Composition, Uses |Full Detail| Types of Aggregates (Coarse and Fine aggregates) | Properties and Use