Bar Bending Schedule is essential in any construction project where reinforcement is required. Bar Bending Schedule is often referred to as BBS. In this post, we will clear all your concepts and other important factors that will help you to understand better.

What is a Bar Bending Schedule?

A Bar Bending Schedule is a list of types of steel reinforcement required for a particular structure. It is comprised of the shape and size of the bar, the diameter of the bar, spacing, cutting length, number of bars, total weight, etc. The preparation of the bar bending schedule helps in estimating the quantities of steel required for the construction project.

Use of Bar Bending Schedule

- 1. It helps to find the total quantity of steel required for the project.

- 2. It also determines the cost of the steel required for the execution of the project.

- 3. It provides the full detail of the cutting and bending of steel and makes it easier to transport it to the site.

- 4. It helps to minimize the wastage of the steel, thereby lowering the cost and making the project economical.

- 5. It shows the proper location and arrangement of the placement of the bars considering approved drawings and specifications.

- 6. It provides ease in checking the reinforcement by the engineers as per the approved drawing and plan.

How to Prepare Bar Bending Schedule?

Review Structural Drawings: Thoroughly study the structural drawings provided by the design team. Familiarize yourself with the project specifications, dimensions, and reinforcement requirements.

Identify the reinforcement sections: Identify the different elements of reinforcement, such as beams, columns, slabs, rafts, and footings. Analyze the drawings to determine the type and size of reinforcement bars needed for each section.

Calculate Reinforcement Quantities: With the help of formulas and calculations, determine the quantity of reinforcement bars required for each portion of the structure. Consider factors like bar length, spacing, lap lengths, and development lengths.

Create Detailed Drawings: After calculating the quantities, create detailed drawings specifying the shape, size, and placement of reinforcement bars. Ensure clarity and accuracy in your drawings to avoid any confusion during construction.

Prepare a Bill of Quantities: Compile all the quantities of reinforcement bars into a comprehensive Bill of Quantities. This document will serve as a reference for billing and cost estimation purposes.

Calculation of Reinforcement

Before proceeding with the calculations of the BBS, you must know a few basic concepts:

- Standard Length of TMT steel bar = 12M

- Development Length = 50d (d = diameter of bar)

- Unit weight of bar (1m) = D2/162

- Density of Steel = 7850 Kg/m3

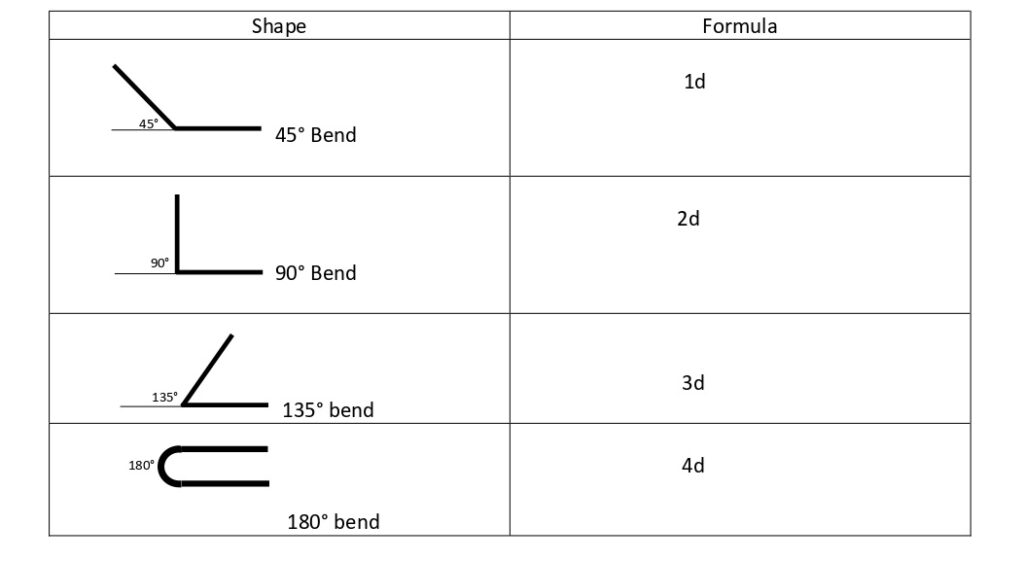

Bend Deductions

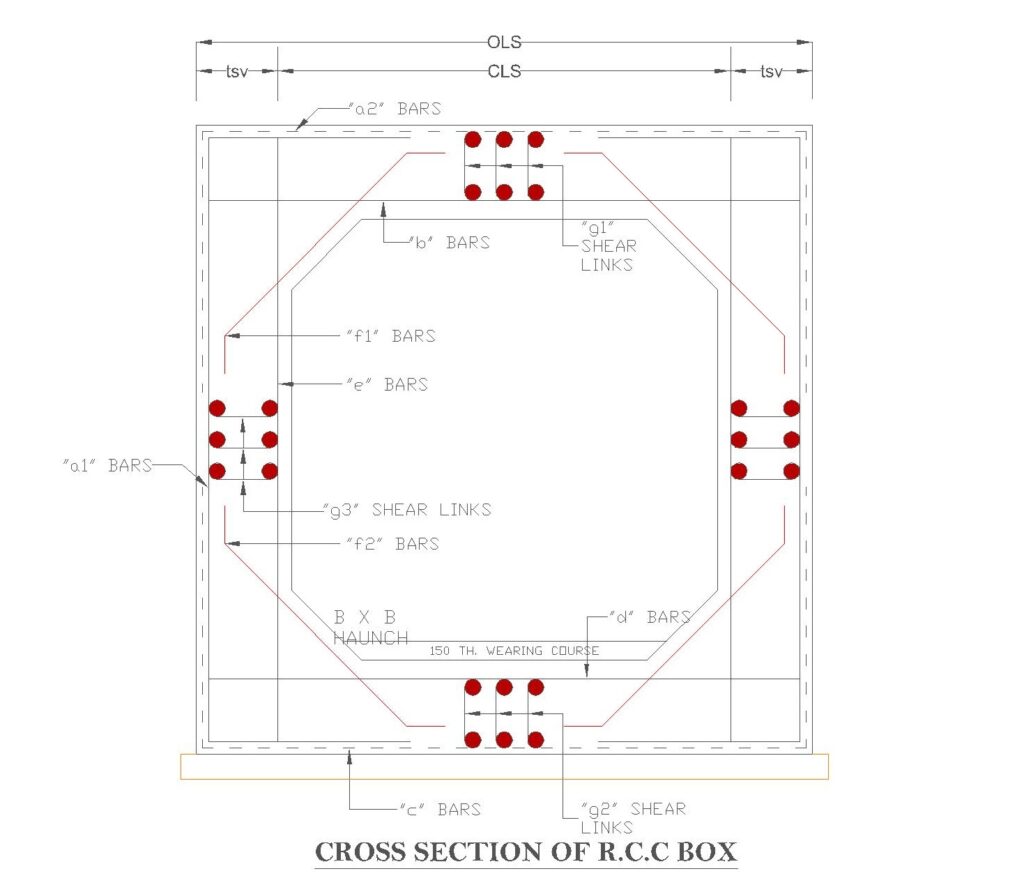

Standard Section of Railway Box Culvert

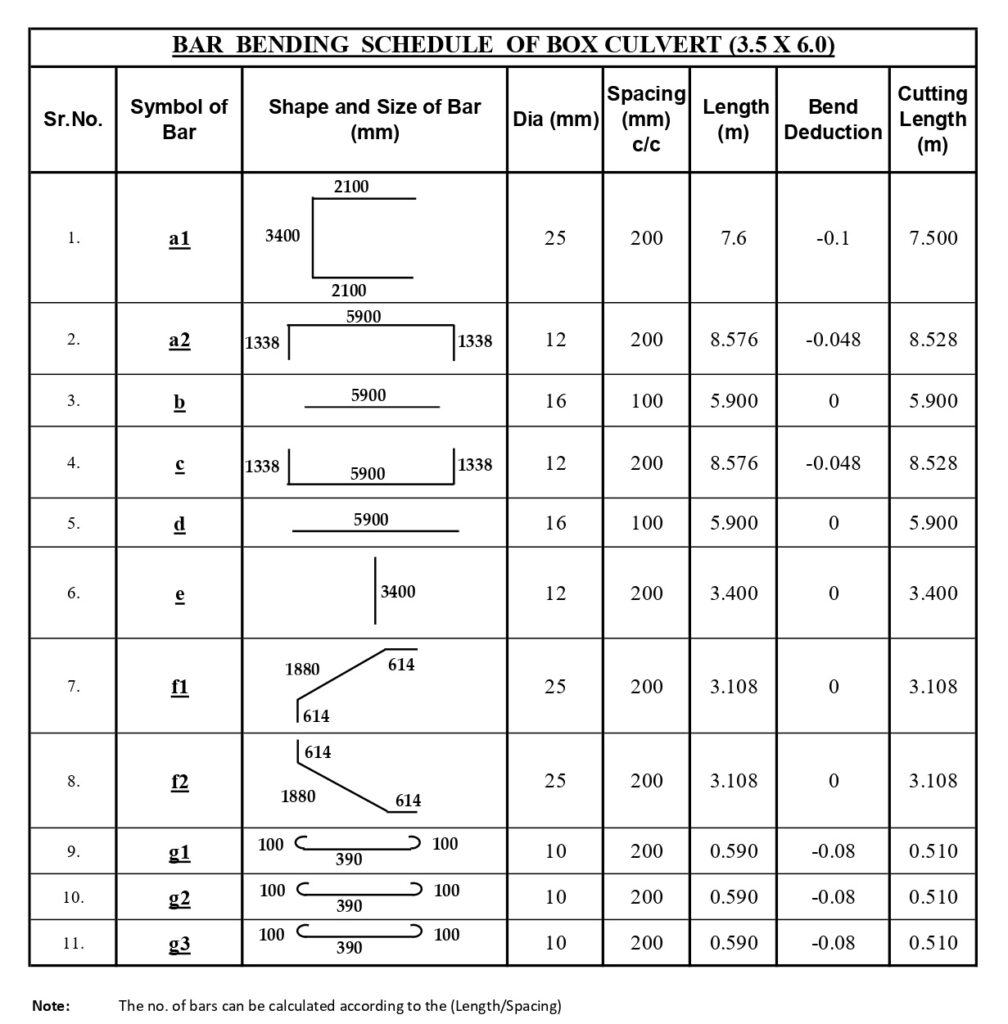

Here is the calculation of the different types and shapes of bars used in box culverts:

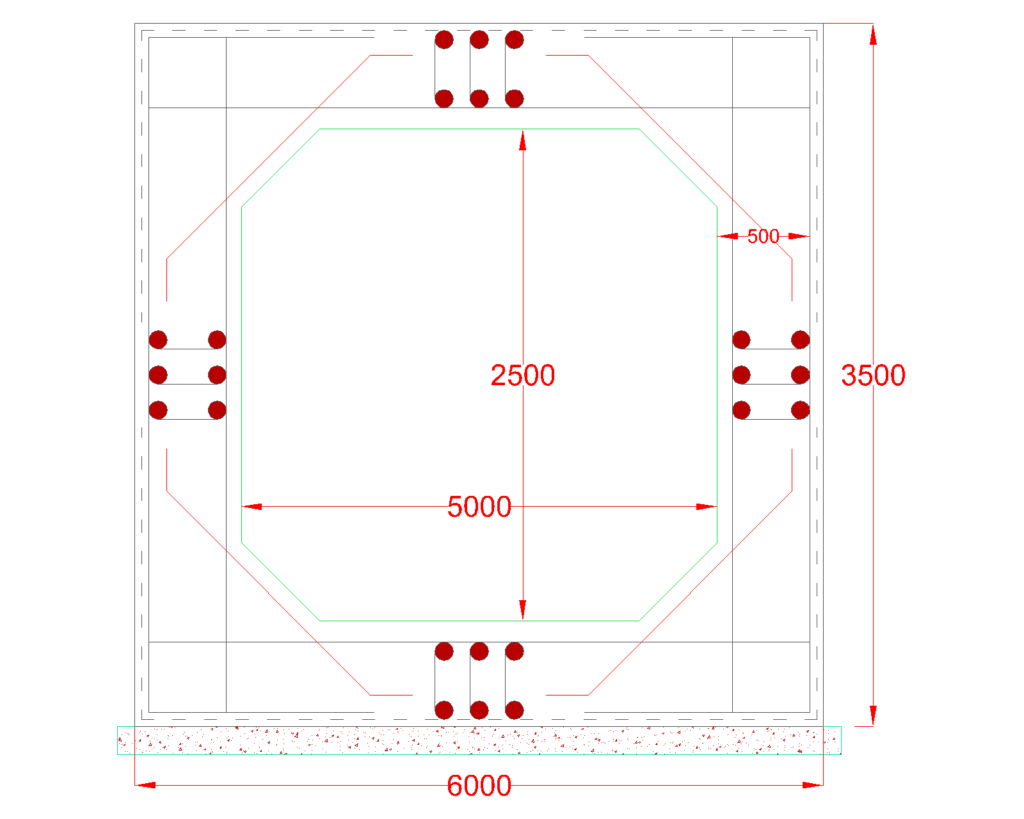

- “a1” bar 25mm

= Total height – clear cover (top & bottom)

=3500 – 50 – 50 =3400 mm

Also, j = tsv + max (0.3 X eff span or DL) – cover

= 500 + (0.3 x 5500) – 50 [ eff span = c/c distance b/w walls]

= 2100 mm [ tsv = thickness of vertical slab]

Bend Deduction = 2 x 2 x d [ DL= Development length]

= 2 x 2 x 25 = 100 mm

Cutting Length = 3400+(2×2100) – 100 = 7500 mm

- “a2” bar 12mm

= Total Span – clear cover (b/s)

= 6000 – 50 – 50

= 5900 mm

Also, k = tst + max (0.3 X eff ht. or DL) – cover – dia [ tst = total slab thickness]

= 500 + (0.3 x 3000) – 50 – 12

= 1338 mm

Bend Deduction = 2 x 2 x d

= 2 x 2 x 12 = 48 mm

Cutting Length = 5900+(2×1338) – 48 = 8528 mm

- “b” bar 16mm

= Total span – cover (b/s)

= 6000 – 50 – 50

= 5900 mm

- “c” bar 12mm = “a2” bar 12mm

- “d” bar 16mm = “b” bar 16mm

- “e” bar 12mm

= Total height – cover (b/s)

= 3500 – 50 – 50

= 3400 mm

- “f1” bar 25mm

= √2 (B + tst + tsv) – 2(√2 + 1) cover

| Clear span or clear ht. | Size of Haunch | Clear span or clear ht. | Size of Haunch |

| Less than 3m | 200 x 200 mm | ≥ 4.5m and < 5.0m | 450 x 450 mm |

| ≥ 3.0m and ≤ 3.5m | 300 x 300 mm | ≥ 5.0 m and ≤ 5.5m | 500 x 500 mm |

| ≥ 3.5m and ≤ 4.0m | 350 x 350 mm | ≥ 5.5 m and ≤ 6.0m | 550 x 550 mm |

= √2 (500 + 500 + 500) – 2(√2 + 1) 50

= 1879.6 say 1880 mm

Also, m = max. [0.1m or DL] – √2 x tst + √2 x cover

= 1250 – (1.414 x 500)

= 613.7 say 614 mm

Bend Deduction = 2 x 1 x d

= 2 x 1 x 25 = 50 mm

Cutting Length = 1880+(2×614) – 48 = 8528 mm

- “g1” 10mm

= tst – 2 x cover – dia

= 500 – 2 x 50 -10

= 390mm

Also, p = 10d, bent at an angle of 135°

= 10 x 10 = 100mm

Bend deduction = 2 x 4 x 10 = 80mm

Cutting Length = 390+(2×80) = 550 mm

“g1”= “g2”= “g3”

To calculate the no. of bars = Length of the section – cover (b/s) / Spacing of particular bar

For “a1” bar =2000 – (2 x 50) / 200 = 9.5 bars (say 10 bars)

Note:-

- The length of the section is mentioned in the approved drawing but here we have taken 20m.

- The spacing, dia of the bar, and clear cover are provided in the sectional drawing.

Calculation Sheet of Bar Bending Schedule of Box Culvert

Advantages of Bar Bending Schedule

- Accuracy: A properly prepared BBS ensures accurate placement and quantity of rebars, reducing the chances of errors that might reduce the structure’s durability.

- Cost Optimization: Cost Optimization: The required reinforcement bars can be accurately determined. It provides bars of required length minimizing wastage and reducing costs associated with excess or insufficient reinforcement.

- Efficient Resource Management: It guides the construction team on the exact placement of reinforcement bars. This makes the construction process easier, minimizes rework, and optimizes labor and equipment utilization.

- Enhanced Structural Integrity: The detailed information provided in the BBS ensures that the reinforcement bars are placed correctly, as per design specifications. This results in enhanced strength and durability of the structure.

- Effective Communication: It keeps transparency between the design team, contractors, and suppliers. It eliminates confusion and misunderstandings by providing a standardized format.

- Time Savings: Providing detailed reinforcement information saves time during the construction phase.

Conclusion

The Bar Bending Schedule is a very useful thing to understand for every civil engineer. It also keeps transparency between the engineers and the construction team by providing the same thing to everyone. While doing calculations, you must analyze the section details and carefully read other instructions given in the drawing.

Also Read:

Types of Steel Reinforcement Properties and Uses Singly Reinforced Beam and Doubly Reinforced Beam Plinth Beam |Purpose Construction and Advantages| Reinforced Cement Concrete Properties, Uses, Advantages |Full Detail|