The compressive strength of concrete is determined by testing the sample of the cube. The characteristic compressive strength of concrete is defined as the compressive strength of a 15cm cube at 28 days in N/mm2. This testing determines the quality and strength of the concrete. By performing this test you can judge the quality of the concrete used in the structure. If you are a Civil Engineer, a student, or a professional, this beginner’s guide will you to understand and perform this crucial test accurately.

Definition of Compressive Strength of Concrete Cube

The compressive strength of concrete is the capacity of concrete to resist the loads acting on it. It indicates the maximum load or stress that can be applied to a concrete cube specimen before it collapses or breaks.

It is a fundamental property that determines the load-bearing capacity of concrete elements. It depends on many factors such as water-cement ratio, material quality, grade of cement, quality control during the production of concrete, etc.

Formula for Compressive Strength of Concrete Cube

It is the load applied at the point of failure to the cross-section area of the face on which the load was applied.

Compressive Strength (N/mm2) = Load (N) / Face area of the Cube (mm2)

Procedure for Compressive Strength Testing of Cube

1. After the curing period, remove the cube from the water and wipe the excess water over it.

2. Lose the rotating part at the top of the testing machine and clear the area for the placement of the cube.

3. Now position the cube in the compression testing machine.

4. The cube should be adjusted at the center of the base plate.

5. Tightened the rotating part with hands from the top, so that it perfectly touches the top of the cube.

6. Now gradually, apply the uniform load at the rate of 140 Kg/cm2/min till the specimen fails.

7. Note the maximum reading and calculate the compressive strength of concrete.

Note:

1. A minimum of three specimens are tested to take the average reading.

2. The cubes whose strength exceeded 15% of average strength are rejected.

3. The cubes are tested after the 7 and 28 days of casting.

Apparatus Required for Cube Test of Concrete

To conduct a cube test of concrete, the following apparatus is required:

Cube Molds: They are made of steel or cast iron, these molds provide the shape and dimensions for concrete cubes. They are available in sizes of 10 cm x 10 cm x 10 cm and 15 cm x 15 cm x 15 cm.

Tamping Rod: A steel rod with rounded ends used for compacting the concrete layers within the cube molds.

Compression Testing Machine: A hydraulic or servo-controlled machine used to apply a compressive load to the cube specimens until failure.

Mixing of Concrete for Cube Test

There are several methods of mixing concrete. The commonly used methods include hand, machine, and ready-mix concrete.

Hand Mixing: Hand mixing is a traditional method that involves manually combining concrete ingredients using shovels or hoes. This method is suitable for small operations where a smaller quantity of concrete is required.

Machine Mixing: Machine mixing is a more efficient and commonly used method that involves the use of mechanical mixers. These mixers can be either batch mixers or continuous mixers.

Ready-Mix Concrete: Ready-mix concrete is a convenient and time-saving option where concrete is manufactured in a batching plant and delivered to the construction site in a transit mixer truck.

Procedure for Preparation of Cube Sample

1. Select the number of cube molds according to the required quantity of concrete.

2. Clean the cube molds properly and tighten them.

3. Lubricate all the specimens with the oil.

4. Now take the fresh concrete directly from the field used to fill the specimens.

5. Fill the mold in 3 layers each 5cm thick.

6. Tamping each layer 35 times with the help of a tamping rod to completely remove the air voids from the concrete.

7. Make sure the top surface is smooth and level.

8. Now place the cubes on the vibrating machine for the removal of any air bubbles or spaces.

Curing of Cubes

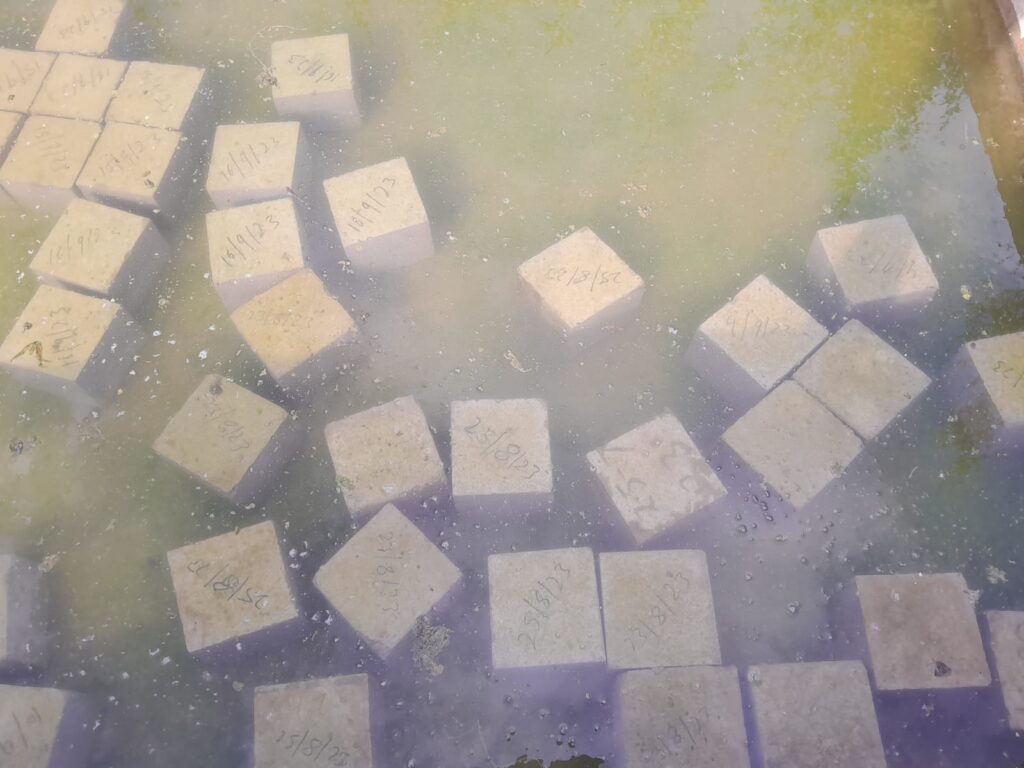

Now place the test specimens for 24 hours in the air for drying. After 24 hours the molds are opened and the cubes are marked. Now all the cubes are kept submerged in a tank or trench filled with clear water.

The proper temperature of water 27°± 2°C should be maintained.

Samples required as per the concrete Quantity

| Concrete Qty in CUM | For 7 Days | For 28 Days | Total |

| 1 -5 | 1 x 3 | 1 x 3 | 6 |

| 6-15 | 1 x 3 | 2 x 3 | 6 |

| 16-30 | 1 x 3 | 3 x 3 | 9 |

| 31-50 | 1 x 3 | 4 x 3 | 12 |

| 51-100 | 1 x 3 | 5 x 3 | 15 |

Calculations for Compressive Strength of the Cube

Size of the cube = 15 cm x 15 cm x 15 cm

Volume of Cube = 0.15 x 0.15 x 0.15 = 0.00337 m3

We know that

Unit weight or Density of MCC = 24 KN/m3

Weight of Cube = 0.003375 x 24

= 0.081 KN or 81 N

= 8.1 KG or 8100 Gms

Compressive Strength = Force / Area

= 1 KN / 150 x 150 mm2 [Cube Face Area = 150mm x 150 mm]

= 1 KN / 22500 mm2

= 1000 N / 22500 mm2

= 1 / 22.5 N/ mm2

= Force / 22.5 N/ mm2

Report of Cube Test of Concrete

It includes the following:

1. Date of Casting

2. Location or Structure

3. Date of 7 days testing

4. Cube Mark

5. Load In KN

6. Strength in KN/ mm2

7. Average Strength in N/ mm2

Strength of Concrete at Various Ages

The concrete becomes more durable with time. The table compares the compressive strength of concrete at various ages to the percentage strength at 28 days after casting.

| Age | Strength percent |

| 1 day | 16% |

| 3 days | 40% |

| 7 days | 65% |

| 14 days | 90% |

| 28 days | 99% |

Compressive Strength of Different Grades of Concrete at 7 and 28 Days

Mean target Strength (fcm) from the desired characteristic strength (fck)

fcm = fck + 1.65 s

S = Standard deviation

fck = Characteristic compressive strength of concrete

| Grade of Concrete | Assumed standard deviation (s) |

| M10, M15 | 3.5 N/mm2 |

| M20, M25 | 4.0 N/mm2 |

| M30, M35, M40, M45, M50 | 5.0 N/mm2 |

| Grade of Concrete | Minimum compressive strength N/mm2 at 7 days | Specified characteristic compressive strength (N/mm2) at 28 days |

| M15 | 10 | 15 |

| M20 | 13.5 | 20 |

| M25 | 17 | 25 |

| M30 | 20 | 30 |

| M35 | 23.5 | 35 |

| M40 | 27 | 40 |

| M45 | 30 | 45 |

Observations

| Sr. no. | Wt. of Cube in gm | Load in KN | Strength of cube in N/mm2 | Average Strength | Remarks |

| 1. | |||||

| 2. | |||||

| 3. |

FAQs

What equipment is used for the cube test?

The Compression testing machine is used for the testing of the cube.

Can the compressive strength test be conducted on other shapes besides cubes?

While the cube shape is the most common for strength testing, the test can also be performed on cylindrical specimens.

How many layers are in a cube testing?

Once the concrete has been prepared according to the mix specification, the cubes are filled with fresh concrete in 3 layers.

What is 22.5 in Cube Testing?

It is the cross-sectional area of the cube whose testing is to be done.

What is 456 in cube sampling?

IS 456:2000 is the code for Plain and Reinforced cement concrete.

What are the sizes of the cube test?

There are two sizes of cubes are available. One is 15 x 15 x 15 cm and the other is 10 x 10 x 10 cm.

But 15 x 15 x 15 cm are mostly used.

Also Read:

M20 Grade Concrete Mix design Reinforced Cement Concrete Properties, Uses, Advantages |Full Detail|

Also Check: Cube mold (150 x 150 x 150)mm Tamping Rod Slump Cone Test Apparatus